Corporate History

Founded in year 2003 as family owned partnership firm, AMIT ENGINEERS started its business with manufacturing of Mechanical, Electrical, Electronics and Refrigeration products for supply to Railways.

Over the next decade, the firm established itself as a reputed supplier of Heating Ventilation and Air Conditioning Systems (HVACs), Switch Board Cabinets, Control Panels, Vacuum Toilets, Micro Processor based Temperature Controllers and AL/SS Water Tanks for Rail application.

In a constant endeavour to expand its product portfolio, the firm is currently in discussion with foreign partners for development of other Products for Rail Application. Company is also open for any other partnerships to enhance its product range and the market value.

Presently, AMIT ENGINEERS, with all India presence, has a team of more than 800 employees comprising of Manufacturing and Maintenance Staff.

Manufacturing Facility

Plant 1

Judi Kalan, Distt. Solan, Baddi, Himachal Pradesh, India

At Amit Engineers, we adhere to the high standards of quality and continuously invest in the latest technology at all levels of development. The firm has two Manufacturing units equipped with advanced technology machineries.

This manufacturing plant is constructed in about 305000 Sq. Ft. of land with all necessary infrastructure and facilities. The plant is well connected with Rail/Road Transport and the nearest Airport (Chandigarh) is 40 KMs from the plant location.

- Manufacturing facilities are equipped with In-house Sheet Metal Fabrication Shop with CNC Laser Cutting and Bending Machines, Qualified Welders to handle TIG/MIG/SPOT Welding and Riveting of Structures.

- In-house Heat Exchanger Manufacturing with required infrastructure and Qualified Brazers.

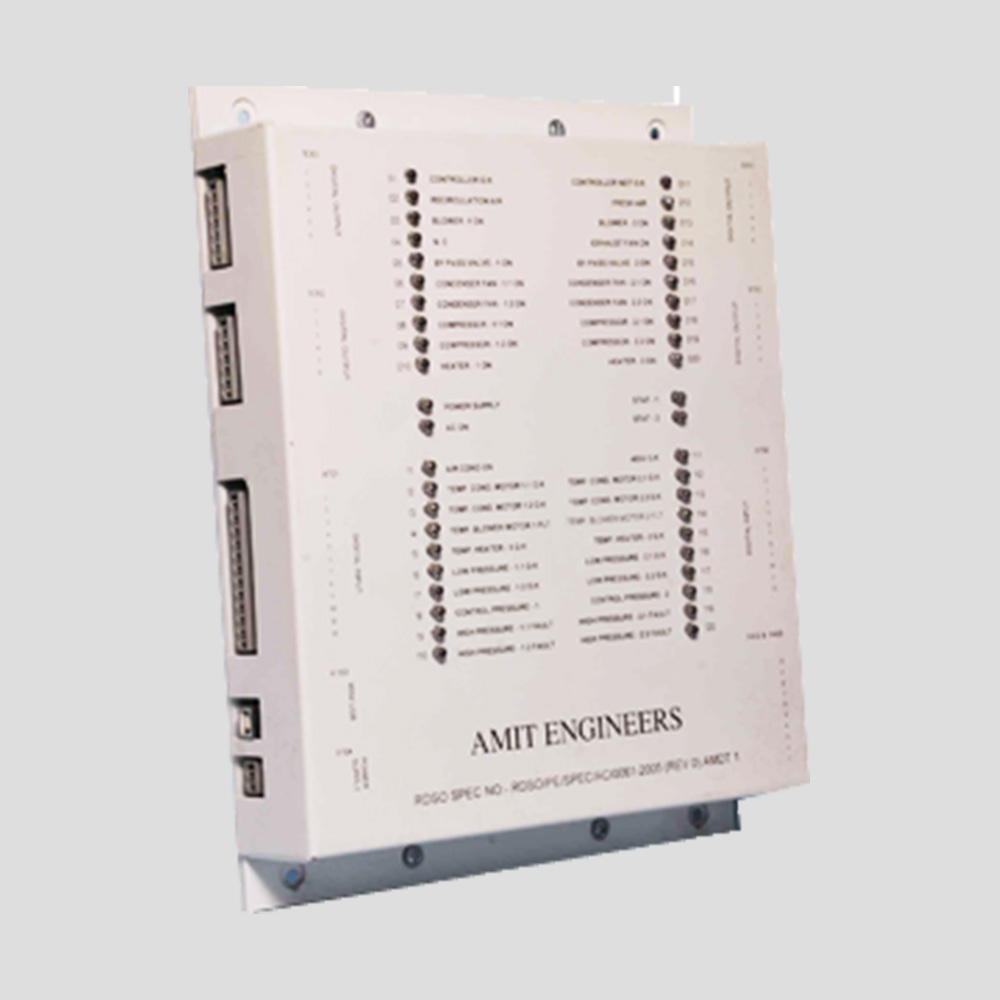

- In-house Design and Manufacturing of Microprocessor based Controllers and Relays.

- In-house facility to Manufacture Electrical Items like Switch Board Cabinets and Electric Control Panels.

- In-house facility to manufacture Bio-Vacuum Toilets for Rail application.

- In-house facility to manufacture Sheet Metal (AL/SS) water Tanks for rail application.

- Psychometric Test Lab to test HVAC systems upto 17 Tons/60KW cooling capacity.

- In-house Wiring Harness facility.

- All required Testing and Measurement Tools.

- Team of Engineers and Supervisors to handle In-Warranty complaints and Annual Maintenance Contracts in the field.

- The manufacturing facility is accredited with quality certifications like IRIS (ISO TS 22163): 2017, ISO 9001: 2015, EN 15085/2 and DIN 6701.

Manufacturing Facility

Plant 2

Nimbua, Tehsil Derabassi, District Mohali

Punjab– 140507, India

This is a newly built manufacturing plant constructed in about 308404 Sq. Ft. of land having all latest and Hi-Tech manufacturing & testing facilities. This plant consists of 4 Bays dedicated to different commodity type. The plant is well connected with Rail/Road Transport and the nearest Airport (Chandigarh) is 24 KMs from the plant location.

Company’s current capabilities can be seen from the following details:

- Design Centre with qualified and experienced Engineers in Mechanical, Electrical, Electronics and Refrigeration fields. Required Software’s are available with this team for designing of Systems as per customer requirements.

- Manufacturing facilities are equipped with In-house Sheet Metal Fabrication Shop with CNC Laser Cutting, CNC Turret Punching and Bending Machines, Qualified Welders to handle TIG/MIG/SPOT Welding and Riveting of Structures.

- In-house Heat Exchanger Manufacturing with advanced infrastructure equipped CNC Machines and Qualified Brazers.

- In-house Design and Manufacturing of Microprocessor based Controllers and Relays.

- In-house facility to Manufacture Electrical Items like Switch Board Cabinets and Electric Control Panels.

- In-house facility to manufacture Bio-Vacuum Toilets for Rail application.

- In-house facility to manufacture Sheet Metal (AL/SS) water Tanks for rail application.

- Psychometric Test Lab to test HVAC systems upto 22 Tons/ 77 KW cooling capacity.

- In-house Wiring Harness facility.

- All required Testing and Measurement Tools.

- Team of Engineers and Supervisors to handle In-Warranty complaints and Annual Maintenance Contracts in the field.

- The manufacturing facility is accredited with quality certifications like IRIS (ISO TS 22163): 2017, ISO 9001: 2015, EN 15085/2 and DIN 6701.

Products

Product Range of the Company primarily caters to Rail segment which includes: