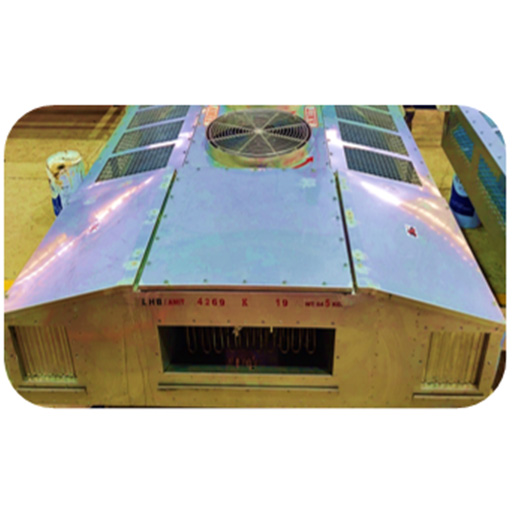

REVERSE CYCLE HVAC

We have developed a reverse cycle air conditioning system that can provide cooling of 24.6kW/7TR and heating of 6kW. It works by reversing the refrigeration cycle of an air conditioner, which typically expels heat from indoors to outdoors. Instead, a reverse cycle air conditioner absorbs heat from outside and transfers it inside. Reverse cycle air conditioners are more efficient than electric heaters, and can be up to 35% more efficient than some ducted air conditioners.

Basic Technical Parameters - German design LHB RMPU Reverse Cycle unit for Semi High Speed Rail Coaches

| Sr.No. | Parameters |

|

| Electrical Requirement | ||

| 1 | Power Supply | 3 Phase, 415 V ±10%, 50 Hz ±2.5% |

| 2 | Power Consumption | 16.5 kVA (max) |

| Capacity |

||

| 1 | Cooling Capacity | 24..6 kW/7 Tr |

| 2 | Heating Capacity | 6.0 kW (Reverse Cycle Heating Concept) |

| Constructional Requirement |

||

| 1 | Design to Ambient (Cooling) | 50°C |

| Design to Ambient (Heating) | 2°C |

|

| 2 | Max Operating Temperature | 57°C |

| 3 | Dimension (LxWxH) | 2200x2000x500 mm |

| 4 | Material for Housing | SS 304 grade S2 Confirming to IS:6911 |

| 5 | Noise Level(Inside the Coach) | 60dB as per UIC 553 |

| 6 | Controller | Microprocessor Controller as per RDSO Spec. No.: RDSO/PE/SPEC/AC/0139-(Rev.1)-2009 |

| 7 | Refrigrant | R-407C |

| 8 | Weight | 645 kg |

| Service condition |

||

| 1 | Ambient | -4 to 57°C |

| 2 | Max. Temp. inside coach Under Sun | 70°C |

| 3 | Train Speed | 200 Km/h |

| 4 | Relative Humidity | Maximum Up to 100% |

| 5 | Atmosphere | Extremly dusty & desert weather |

| 6 | Shock & Vibration Srandard | IEC 61373 |